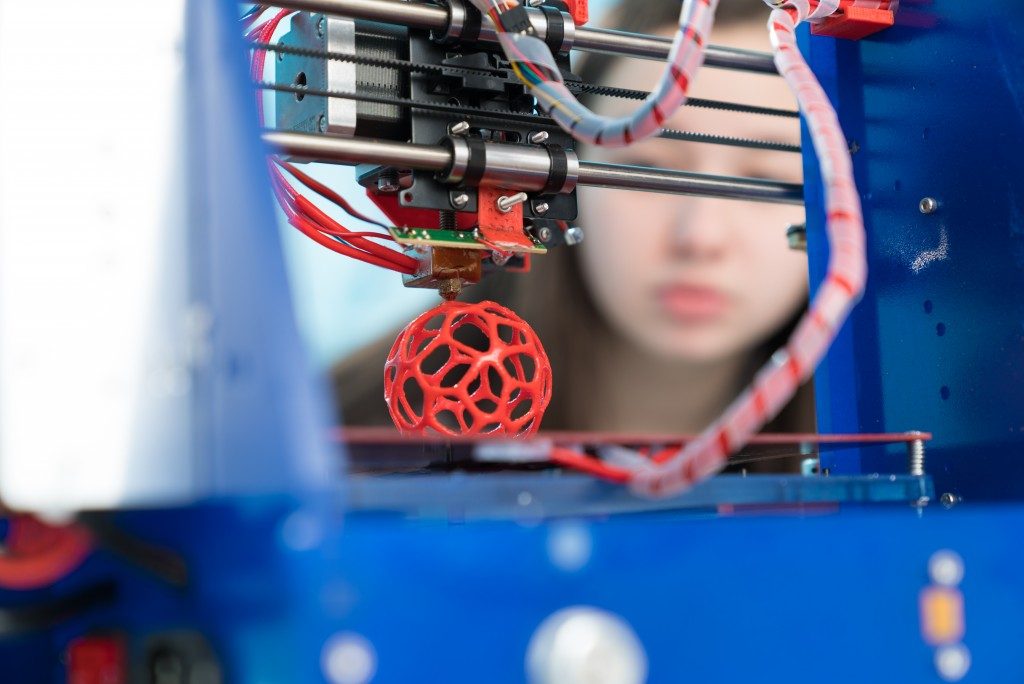

3D printing has changed production and manufacturing processes and allowed them to become easier and more creative.

It’s found success in applications across the aviation, education and healthcare industries. When you’ve decided to use 3D printers to design models for your business, you need to understand that they’ll differ in terms of their capabilities and design restrictions.

You’ll have to be prepared with the designs you want and how detailed you want your model to be before investing in any process.

Design Considerations

Overhangs

The process of 3D printing works by building a structure layer by layer. This means each layer of material has to be printed on top of another. But a design could also include overhangs. These are areas in a model that are partially or not at all supported by the layer below. Printers will have limits in terms of the angle the material can be built on without needing proper support. Generally, however, it’s more beneficial for you to limit the overhangs in your design to promote greater overall support.

Wall Thickness

Wall thickness is another consideration. Generally, 3D printing processes accurately produce design features that are thick. Accuracy can decline with extremely fine details and thicknesses. Being aware of the specifications and capabilities of your printer means you can better be able to remain between its boundaries of high accuracy. You won’t run into problems when trying to print designs that are too small. It’s good practice to design thicker designs to ensure printing goes smoothly.

Warping

The materials used by 3D printing processes undergo physical changes. A laser melts, scans, or sinters the materials before they undergo a process of solidification. Because they undergo heating and cooling processes, the parts may end up warping during printing.

The risk of warping can be managed with the use of properly calibrated machines and the right amount of surface adhesion between the material and the print bed. You can try and avoid large and flat surfaces and go for round corners when you’re designing 3D models, as flat parts are more susceptible to warping.

Amount of Detail

You may require your 3D printer to create models with intricate details. But you have to take into consideration the capabilities and mechanics of your printer, as well as determine the appropriate layer height. What’s the minimum feature size the printer can handle and produce with a high degree of accuracy? You’ll probably be able to get more information about how exactly each printer can form your design from suppliers of 3D printers.

The materials and processes you end up using for your printer can significantly affect the speed and cost of the model you make. So, important decisions can include even the smallest details involved in designing your model.

Prototypes

When you’re just starting out with a 3D printer, you may need several designs to perfect your model. This type of printing allows you the ease and convenience of drafting several different designs so you can come up with more than one prototype. It’ll then be easier to decide which specific one you want to put on the market. You can replace and change out the parts you think will suit your needs better.

The ability to do this saves you both time and money. You’re essentially able to conduct research at low costs and negligible prices to arrive at the exact product you want.