- Incorporating advanced technologies into production enterprise operations offers significant benefits such as increased efficiency, lower costs, and improved quality control.

- Artificial Intelligence (AI) allows production enterprises to quickly detect potential issues with their equipment or analyze defects in real time.

- Robotics provides advantages such as non-stop operation and less maintenance compared to traditional machines and equipment.

- Specialized software helps production enterprises increase efficiency while reducing costs by automating mundane tasks.

In today’s fast-paced business environment, it is essential for production enterprises to keep up with the latest technologies in order to remain competitive. With the help of advanced technology, production enterprises can streamline their processes and increase efficiency, ultimately leading to higher profits. This article will discuss the technologies that can significantly improve your production enterprise.

1. Internet of Things (IoT)

The Internet of Things (IoT) has revolutionized the manufacturing industry by enabling machines and devices to communicate with each other and share data in real time. This technology allows production enterprises to monitor their entire supply chain, from raw materials to finished products, ensuring that every step is optimized for maximum efficiency.

Real-time monitoring of equipment

With IoT sensors installed on machinery and equipment, production managers can receive real-time updates on machine performance and detect any issues before they become major problems. This reduces downtime and maintenance costs while increasing productivity.

Predictive maintenance

IoT also enables predictive maintenance, which uses data analytics to identify potential equipment failures before they occur. This proactive approach to maintenance saves time and money by preventing costly breakdowns and reducing the need for unscheduled repairs.

2. Artificial Intelligence (AI)

Artificial intelligence (AI) is another technology that can significantly improve production enterprises. AI-powered systems can analyze large amounts of data quickly and accurately, providing insights into production processes that would be impossible for humans to detect.

Quality control

With AI-powered systems, businesses can quickly identify potential issues with their equipment or analyze data from cameras on their production lines in order to detect defects or anomalies in real time. This helps to ensure the quality of products and prevent costly batch rejections or customer complaints.

Resource optimization

AI also aids in resource optimization by analyzing large amounts of data related to the supply chain, from raw materials to finished products, in order to identify areas where improvements can be made. From this analysis, businesses can take proactive steps toward optimizing resources and streamlining processes for maximum efficiency and cost savings. Furthermore, AI-based systems can also provide decision support for managers when making decisions related to operations, enabling them to make informed decisions quickly without risking any negative impacts on production operations.

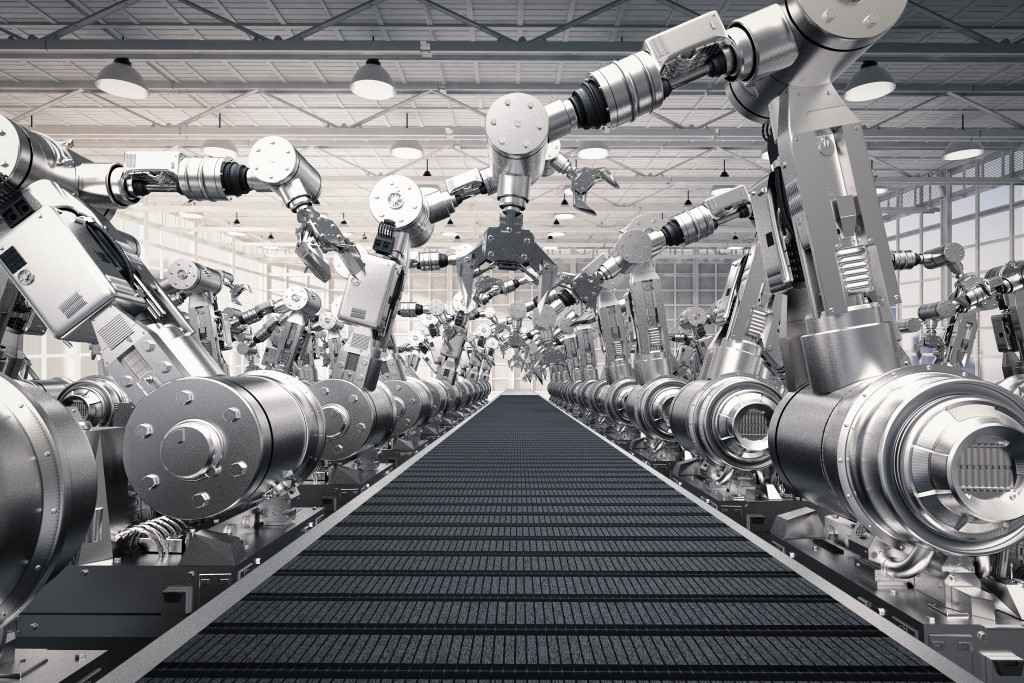

3. Robotics

Robotics can provide a number of advantages to production enterprises. For instance, robots are able to work non-stop, eliminating the need for breaks or rest periods. This can greatly increase productivity, as there is less downtime due to human fatigue. Additionally, robots can be programmed for specific tasks and processes, allowing for more precise and accurate results than humans. This also improves consistency in production lines and reduces the chance of errors and defects.

Higher work efficiency

Robots can also operate at a much faster speed than humans and can complete tasks in significantly less time. This increases efficiency and lowers costs since fewer resources are needed for a given task or process. Furthermore, robots can work in hazardous environments that would be too dangerous for human workers, allowing production enterprises to access new markets that were previously inaccessible.

Less maintenance

Robots also require little maintenance compared to traditional machines and equipment. As a bonus, they are more durable than their manual counterparts due to their heavy-duty construction materials and lack of wear from repeated use. This makes them ideal for long-term industrial applications where reliability is paramount.

4. Specialized Software

Specialized software can significantly optimize production enterprises, providing the tools and functionalities to streamline processes, maintain data accuracy, and improve overall performance. By automating mundane tasks and providing real-time visibility into operations, specialized software helps production enterprises increase efficiency while reducing costs.

Better data accuracy

One of the significant benefits of specialized software is improved data accuracy. Production managers can make better decisions with up-to-date information by automatically tracking inventory levels and demand trends. Additionally, automated validation rules help ensure compliance with industry regulations by keeping data accurate and consistent across the enterprise. Optimizing net content control processes using reliable software also helps ensure that your business complies with consumer protection laws.

Improved scalability

Specialized software increases scalability by enabling production enterprises to quickly expand their operations without worrying about manual errors or costly downtime. This allows businesses to respond quickly to changing market conditions or customer needs without having to invest heavily in new hardware or personnel.

Incorporating advanced technologies such as IoT, AI, robotics, and specialized software into your production enterprise operations offers significant benefits, including increased efficiency, lower costs, and improved quality control standards, among others. It’s important not only for businesses but also consumers who rely on these businesses’ products and services; thus investing resources towards adopting new technologies becomes paramount if you want your company to stay relevant within an increasingly competitive market.